TrussForte Stair Treads products have been engineered to suit customer provided stingers / supporting structures. This new addition to our product range is Australian designed and manufactured. These stair treads incorporate our expertise and skill with the manufacture of our expanded metal products, which has been utilized as the tread surface. Stair treads are fully fabricated and welded from structural mild steels, expanded metal mesh and laser cut side bolt plates.

TrussForte Stair Treads products have been engineered to suit customer provided stingers / supporting structures. This new addition to our product range is Australian designed and manufactured. These stair treads incorporate our expertise and skill with the manufacture of our expanded metal products, which has been utilized as the tread surface. Stair treads are fully fabricated and welded from structural mild steels, expanded metal mesh and laser cut side bolt plates.

The TrussForte stair treads have been designed in accordance with AS1657:2013, and have been fully load tested for compliance with service and ultimate load ratings, as well as deflection characteristics, using NATA calibrated equipment. Stair tread load testing has been carried out as specified in appendix D of AS1657:2013, in particular sections D4.1-D4.3 inclusive. Stair tread test results obtained actually surpass the Australian Standards criteria with maximum deflections of less than half the allowable deflections listed for the specified service loads. Stair treads have additionally been tested in excess of the advised ultimate load values without any failures.

Stair tread loading and testing is based on the stair treads being structurally independent of the adjoining elements. Compliance with the Australian Standard AS1657 designed live load of 2.5 kPa, as well as the tabulated 4.0 kPa and 5.0 kPa loads listed in table 3.1 of Australian Standard AS1170.1, if applied to individual stair treads will result in loads and deflections that fall within the test criteria of AS1657.

Note that compliance/testing of complete stair tread assemblies is the responsibility of the staircase designer/fabricator. Testing for every scenario and configuration of staircase design due to the vast scope of possible arrangements in regard to rises, goings and fitment to side or bottom stringer configurations of various materials, sections sizes and staircase lengths is not with the scope of supply of our stair treads.

As well as meeting Australian Standard load requirements, our stair treads also comply with the specified resistance to slip as indicated in AS1657:2013 and the current National Construction Codes (NCC) / Building Codes of Australia (BCA). The stair tread surface has been fully tested accordingly to AS4586:2013 / AS4663:2013, using NATA certified and accredited equipment, so that you can be assured that our products meet all the current compliance requirements within Australia. Testing has been performed with both the Wet Pendulum Slip Test as well as the Oil-Wet Inclining Platform Slip Test. Note that compliance to either of these test methods is required (not both), however, we have tested to both criteria for substantiation.

To our knowledge, our stair tread products are the only stair treads on the market that have been certified and tested to the extent indicated.

For reference, the following tables have been reproduced from AS4586:2013 showing the relative class ratings for both Wet Pendulum Slip Test and Oil-Wet Inclining Platform Slip Test.

Stair tread configurations are available for conventional bolted side mount fixing, or convenient bottom mount fixing, which will suit many common design standards that architects and engineers have adopted.

TrussForte stair treads can be used in any domestic, commercial or industrial application, and come in five (5) standard tread width sizes (600mm, 750mm, 900mm, 1200mm & 1500mm). Note that these sizes are all meet the Australian Standards criteria.

Stair treads are also available in four (4) tread depths sizes (225mm, 275mm, 325mm & 375mm) which are sized to meet Australian Standards. This choice of tread depths provides a vast array of designable Riser and Going configurations for any application, whether it is to minimise staircase space requirements, fit existing floor plan areas, or provide architectural inspired concepts.

Additionally, we offer our stair treads with a corrosive resistant hot dip galvanised coating, or a raw (black) mild steel finish which customers can then finish in their choice of coatings (e.g. painting, powder coating, electroplating, etc.)

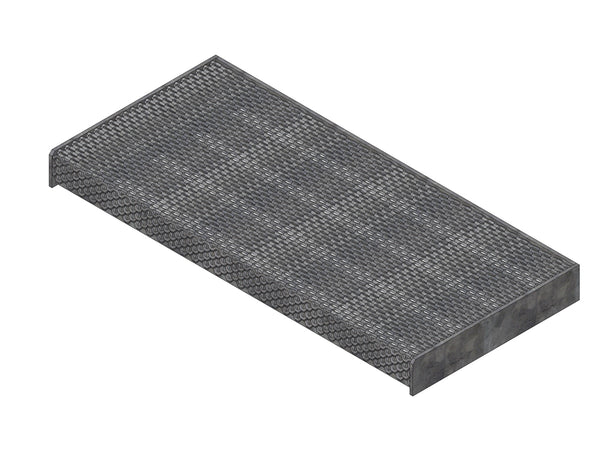

As described above, our stair tread design incorporates the use of one of our versatile expanded metal mesh patterns as the tread surface. Its characteristic saw tooth profile provides a decorative architectural look that is functional and aesthetically pleasing to the eye. The expanded metal pattern provides an extremely durable grip surface, and has a minimal aperture size of approximately 10mm x 3.5mm, which is suitable for rapid drainage in wet areas, as well as being heel safe for all types of footwear. The expanded metal mesh surface is also strong and relatively lightweight, and will allow dry debris from shoes to readily fall through the tread without build up. At the same time, the tread surface aperture size is small enough to prevent accidental dropping of keys, tools or valuables from falling through the mesh pattern. Note that the prevention of objects larger than a 15mm spherical diameter are also required to be prevented from passing through stair treads/landings that are above work areas. This is a requirement of Australian Standard AS1657:2013.

Stair tread nosing is also a continuation of the tread mesh surface pattern. We have engineered this feature in a wraparound design to provide a clean continuous look that gives the stair tread its aesthetic appearance.

All stair treads are manufactured with the aid of suitable jigs. This ensures that all items are consistent in size and configuration (whether they were made last month, or newly manufactured next week, or next year).

$113.30

Pick up now available in store. Or please call, email to discuss delivery. All side mount stair treads are manufactured using 65 x 5mm thick side plates with 14mm holes...

$121.00

Pick up now available in store. Or please call, email to discuss delivery. All bottom mount stair treads are manufactured using 5mm thick structural steel with an expanded metal top/nose...