Some of the simple and common terms used to describe expanded metal mesh are briefly covered below. These terms are useful to know when choosing and ordering the product.

Raised expanded metal is the form the product takes when it goes through the expanding process described earlier. The strands and knuckles are set at a uniform angle to the plane of the sheet. This adds strength and rigidity, allows air circulation, and distributes the load on the metal to the supporting frames. No additional pressing operations are needed.

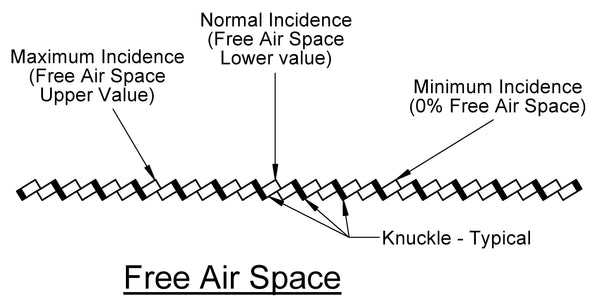

A knuckle is the intersection of two strands and is always the width of two strands.

Thickness is the actual measurement of the thickness of the mesh material measured at the knuckle.

Strand Width is the feed length of material that is passed through the press at each of the downward shearing/pressing operations. It is the measurement that is perpendicular to the material thickness. Note there are 2 strand width's per knuckle.

SWM is the distance from a point on a knuckle to a corresponding point on the following knuckle measured across the short way of the diamond shaped hole. This distance is also sometimes referred to as ‘‘pitch’’.

LWM is the distance from a point on a knuckle to a corresponding point on the following knuckle measured across the long way of the diamond shaped hole. This distance is also sometimes referred to as ‘‘pitch’’.

Free air space is the percentage of the viewable expanded sheet area that is space, as opposed to metal material. Approximate values are provided in the product selection chart. Values for raised expanded metal vary from lowest value at normal incidence (i.e. when viewed with the sheet held at right angles to the line of vision) to highest value at maximum incidence (i.e. when viewed with the sheet slanting so that the strand width is parallel to the line of vision, thus presenting a greater free area).

Guillotining is an operation to cut expanded sheets to the requested finished overall size (SWM x LWM size) (within the guillotining tolerance). When guillotining (trimming) in this manner, please be aware that the size requested may not coincide with a full multiple of the SWM or LWM pitch. This will result in open diamonds on one or more of the sheet edges.